$900 for 1.5cm 3D-printed steak: Scientists construct wagyu-like structure using bioprinting tech

Conventionally, cultured meat companies produce cultured beef by assembling muscle fibres, which is essentially the main part of animal meat.

But animal meat isn’t all about the muscle, with the presences of fat tissues and blood vessels play a role in giving meat that steak-like structure.

For cultured beef, creating a steak with a composition and a structure similar to real steak still remains a challenge, which involve fat cells and aligning muscle cells together.

“Wagyu has a marbling structure due to its fat composition. So, we wanted to construct a structured wagyu beef similar to the actual wagyu beef by assembling three types of bovine cell fibers (muscle, fat, and vessel),” said Professor Michiya Matsusaki from the Graduate School of Engineering, Osaka University.

Matsusaki and his team published the findings in Nature.

How it works

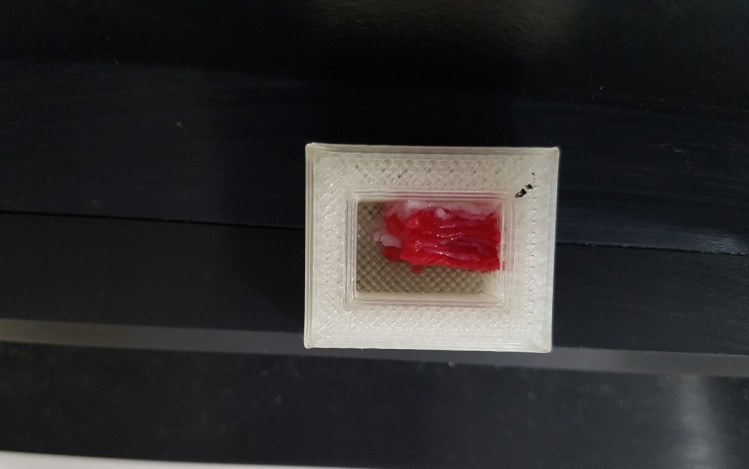

In this study, a total of 42 muscle fibres, 28 adipose tissues, and two blood capillaries were constructed by tendon-gel integrated bioprinting and manually assembled to fabricate steak-like meat.

Matsusaki explains more in this video.

“Up to our knowledge, this is the first report to demonstrate the fabrication of whole-cut cultured meat-like tissue that was composed of three types of primary bovine cells isolated from an edible meat block and was modeled into a real meat’s structure,” researchers said.

At present, the demonstrated cultured steak-like tissue is still inedible, which Matsusaki explained was because of the use of a non food-grade culture media.

“We are working on switching to a food-grade culture, and by this fiscal year, we can fabricate an edible meat.”

According to Matsusaki, it cost around JPY100,000 (US$900) for the construction of a 1.5cm piece of meat.

Cultured meat market

The cultured meat industry has been growing and attracting significant investments in recent years. There’s Israel’s Aleph Farms and Dutch Mosa Meat making cultivated beef, US’s Eat Just with its cultured chicken, not to mention cultured seafood by Singapore’s Shiok Meats and Hong Kong Avant Foods.

So far, some of these firms have indicated interest in going to market soon, but only Eat Just’s cultured chicken ingredient has been granted regulatory approval for sale in Singapore.

Of these companies, only some are using 3D-bioprinting, which is still relatively new in the cultured meat space.

One of these companies is Aleph Farms which unveiled a 3D-bioprinted ribeye this year, and plans to bring its cultured meat to market next year.

Various tissue engineering techniques such as cell sheet engineering, cell fibre engineering, cell culture on a 3D-printed scaffold, and 3D cell printing could be used to achieve a steak-like structure.

Among these, 3D cell printing is promising due to its advantages of scalability and controllability of structure and composition.

Matsusaki predicts companies will start commercialising products using 3D-bioprinting in the next three to four years.

Source: Nature

https://doi.org/10.1038/s41467-021-25236-9

“Engineered whole cut meat-like tissue by the assembly of cell fibers using tendon-gel integrated bioprinting”

Authors: Michiya Matsusaki, et al.