FNA DEEP DIVE: FOOD SAFETY AND TRACEABILITY

Beyond barcodes: How CP Foods, Golden Agri, Thai Union and more are tapping new tech for safety and provenance

In this edition of the FNA Deep Dive, we take a close look at the rapid growth of this sector in terms of format and scale, and some of the newest options being developed.

Food safety and traceability are undeniably closely intertwined, particularly in a large region like Asia Pacific where supply chains and networks are long, complex and opportunity for untoward interference is rife.

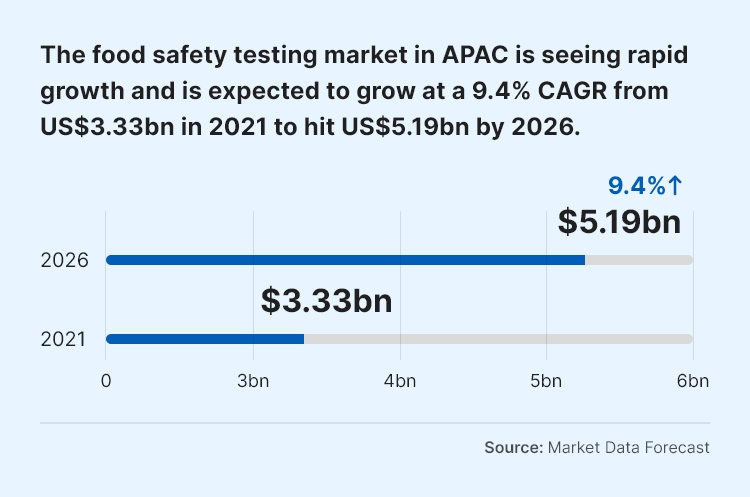

Some of the most major issues faced by the industry in the region include high rates of food fraud and adulteration, food contamination, a lack of information and more – and although technologies to track products across the supply chain like the scanning of barcodes and QR codes have not been around for all that long, given the complexity of the food supply network, there are instances when the information these can encode and provide to both the product producers and consumers is no longer sufficient to satisfy demand, particularly with a rise in consumer awareness about food safety and product origins.

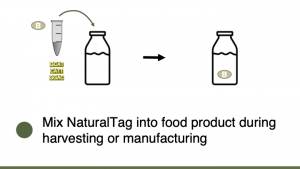

As such, various new technologies are appearing within the market to target existing loopholes, with one example being Singapore-based Natural Trace – the firm has developed proprietary traceability technology NaturalTag based on PCR testing which utilises an in-food DNA concept to tag individual batches of food products.

“NaturalTag is essentially a microbial tag that is produced from dairy, where DNA is extracted and selected to create unique tags based on the DNA sequence that are added, either in liquid form or powdered form, to the fod or beverage product that needs to be tagged and traced,” Natural Trace Venture Builder CL Goh told FoodNavigator-Asia.

“Once this tag has been added to the product, essentially it has now become a tamper-proof watermark that can be detected and read back anywhere along the supply chain to identify the relevant ingredients in the product.

“This patented innovation is food-grade so completely safe, non-GMA and all-natural, and can help [industry players] to prevent, detect and manage foodborne risks, and improve human health.”

NaturalTag is the world’s first solution of its kind, and boasts the ability to trace every single ingredient in a food product directly.

“Most traceability solutions today, including blockchain, barcodes and serial numbers, are external, non food-grade tags [whereas] NaturalTag is the only food-grade, in-product tag solution that allows [the tracing] of every ingredient in every product along each stage of the supply chain,” Goh added.

“Only a minimal quantity of NaturalTag microbial identifiers are needed – the unique serial identifiers are captured into a traceability report, which generates origination information of each ingredient in a food product, [and this is] stored in Natural Trace’s cloud solution [to be retrieved where required].”

He highlighted that the firm is already piloting the traceability with multiple types of food and beverage products from around the region and the world, and is working with the National University of Singapore for product testing. Watch the video below to find out more.

Traceability at a major scale

That said, this is not to say that conventional traceability technologies which employ digital platforms with scanners and external tagging are not useful – in fact, the scale at which these are being utilised within the food and beverage sector today is wider than ever before.

This is extremely important for industries where providing proof of authenticity or certain attributes such as sourcing sustainability is crucial to drawing in and maintaining consumer interest, for example in the palm oil sector.

“Whether it comes to proving food safety or sustainability, today traceability has become an essential part of the food supply chain, especially for a major commodity such as palm oil which is used in the manufacturing of so many different types of food and beverage products,” the world’s second-largest integrated palm oil firm Golden Agri-Resources (GAR) Chief Sustainability and Communications Officer Anita Neville told us.

“Consumers want to know what they are eating is safe and they want to know where the ingredients in their foods come from – which in turn means that manufacturers now need access to this sort of information to provide their consumers with that security and peace of mind they need to make new and repeat purchases, and this is where traceability comes in.

“So even for a company of GAR’s size, and despite the fact that we deal with over 500,000 hectares of palm oil plantations and hundreds of thousands of third party suppliers, we knew that it was necessary for us to invest in traceability technology to build and retain that trust with manufacturers, who can in turn convey that confidence onwards to product consumers.”

Over 96% of the firm’s palm oil sourcing has now achieved full supply chain traceability, and it plans to put in even more work towards reaching the 100% goal, the benefits of which will then also be felt by some of its major consumers including Nestle, Mars and Hershey.

Although it is conceivable that at some point in the future in-food DNA traceability and tagging technology might be applicable for a supply chain as large and complex as this, at this point in time the firm and others like it still need to rely on traceability technology involving applications, handheld scanners, mobile phones, and various digital platforms.

Traceability and food safety

Similarly, many major food and beverage firms further downstream of the food supply chain within the APAC region have also recognised the importance of highlighting their usage of technology to ensure food traceability and food safety in their products, and this is especially so for firms that handle meat and seafood products.

For example, Charoen Phokphand Foods (CPF) bas developed its own CPF Digital Traceability system with a blockchain technology component to be used throughout its value chain from farming to end-product distribution, complete with an internal traceability policy.

The system will eventually be used to trace every business that the firm covers, from pork to poultry to shrimp and ready-to-eat foods, and will first be focused on its APAC markets including Thailand, Vietnam, Malaysia, Laos, Cambodia, China and India.

“[CPF has] implemented this traceability system to all our businesses in Thailand and invested in this for [several other] countries we have presence in - This is to ensure the transparency of information traceability at every step, starting from feed production to distribution,” CPF Vice Preseident Dr Payungsak Somyanontanakul said.

“We have the advantage of operating under a vertically integrated business from animal farming [to] meat processing [to] product manufacturing, therefore we have full traceability throughout our supply chain [such that] we can track the quality of food from the feed mills to the end products.”

For CPF, one of the key reasons for its traceability focus is food safety, due to rising health awareness amongst consumers in the region leading to fears of meat or meat products contaminated with disease, drugs or additives.

“Food safety is definitely one of the key trends defining consumer purchasing for the next decade,” said CPF Executive Vice President for International Trade and Business Development Anat Julintron.

“There is rising concern over things like hormones, antibiotics and other modifiers, thus CP Foods has taken special care to use none of these when rearing the animals and producing our meat [in addition to] producing fresh meats with high food safety and high nutritional value, including our Benja Chicken and Cheeva Pork which [come from] from superfood-fed animals raised with high animal welfare standards.

“We have also developed probiotic-fed meats under the CP SELECTION for consumers that are in search of that extra healthy quality in their meat, so that probiotics can be gotten without needing additional medication or supplements.”

Out of this world tracking

Others such as seafood giant Thai Union have looked beyond conventional tracking technology to the utilisation of satellite imaging for its traceability efforts, particularly when it comes to shrimp farming.

“Accessing reliable information for shrimp farms across wide geographies can be both challenging and expensive [which is why] we see great potential in the use of satellite imaging to improve our transparency, as well as to assess risk and monitor the performance of our shrimp farms,” Thai Union Group Director of Sustainability Adam Brennan told us.

“Thai Union [has been] piloting the use of satellite imaging/earth observation/ remote sensing since 2021 for shrimp farming operations in collaboration with a satellite data analytics company and a supply chain traceability company [with the] main goal of generating Key Data Elements (KDEs) for these that are automated, independently verifiable and cost effective.

“[This data has strong potential to benefit both food safety and sustainability efforts in the seafood sector], by supporting sustainable farming practices using insights into shrimp populations, farm health, contamination and more.”

Blockchain still ruling the roost

At this point in time, the technology that most food firms and even governments still find the most relatable for traceability is blockchain, given that this has been around for several years and has proven its mettle in terms of data storage and security.

In a market like Australia where there is strong focus on ‘Brand Australia’ product provenance and food fraud prevention, blockchain has been used to ensure that Australian products are not misrepresented in the international market.

“Food fraud costs the global food industry an estimated US$40 billion each year, [and the major industries in Australia] that tend to be affected include dairy, wine, livestock and seafood with multiple reports of Australian agricultural commodities overseas,” the Australian Ministry of Industry said via a formal report.

“New technologies [such as blockchain] will enable increased scrutiny and produce-testing at any stage along the supply chain [and] provide reliable, secure tracking of provenance.

“In wine for instance, most stages of the wine supply chain have is a need for the transfer of data or accreditations - This presents a tremendous opportunity for blockchain solutions to combine with other technologies such as the Internet of Things (IoT) to generate efficiencies and to remove red tape, [as well as to] add transparency, data sharing and efficiencies to the wine sector,”

“Blockchain technology also has the potential to enable immutable record-keeping of winemaking data, to facilitate future compliance and production audit activities, [and] creating a trusted source of data [which can] unlock export and import process efficiencies as supply chain partners digitise in the future.

“Sharing critical traceability data [also] enables differentiation and communication with a broad set of consumers across a variety of markets.”

Australia is not alone in this – thousands of miles away in India, local governments are doing this too, such as the Government of Telangana which is utilising blockchain start-up TraceX’s technology to track its agricultural produce.

Start-ups such as TraceX with a food and agricultural blockchain focus are growing rapidly all over India and the APAC region, standing testament to the industry’s current faith in blockchain for secure traceability, and it remains to be seen whether newer technologies such as NaturalTag could overtake its lead in the next decade.