Light disruption: Singapore uni spin-off develops tech to disinfect and preserve food and surfaces

The firm SafeLight has developed a visible light technology of the same name to kill microorganisms and preserve food.

CEO Dr Vinayak Ghate told FoodNavigator-Asia, the technology could be used to preserve fruits and vegetables in the cold chain, as well as food surfaces in processing plants.

The company hopes to grab a slice of the local disinfection market in food processing which is valued at SG$14m (US$10m). Globally, the market size is SG$92bn (US$66m) and expected to grow at a CAGR of 4.4%.

Research of this technology started in 2011, and the firm is now planning to commercialise and conduct pilot trials.

Current preservation and disinfection methods

Dr Ghate said the motivation behind SafeLight was to create a tech solution to operate alongside refrigeration.

“That is because refrigeration only slows down microbial growth but does not kill any microorganisms. Hence, we needed a technology that could supplement refrigeration by killing microorganisms.”

In addition, for contact surfaces, current methods of surface disinfection were episodic, and the firm saw a need for technology that can be used against bacteria continuously.

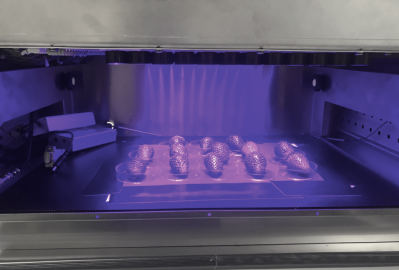

He said SafeLight uses ‘visible light’, that can be implemented continuously, or at various points in the supply chain, from the farm to fork.

It claims to kill microbes from bacteria, yeasts, moulds to viruses.

Preserve and protect

It works by targeting light-sensitive compounds (photosensitisers) that are naturally present inside bacterial and fungal cells.

The compounds once excited by SafeLight, will generate reactive oxygen species (ROS) which are toxic to the cells and ultimately lead to cell death.

Dr Ghate explained that the longer the use of Safelight, the greater the disinfection rate. “It can disinfect up to 99.999% and beyond. However, the real value of the technology is in its continuous usage, not its speed.”

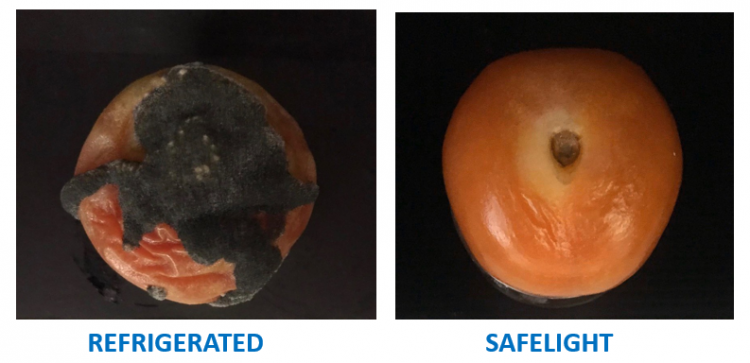

In one example, the firm contaminated tomatoes artificially with spoilage mould, Rhizopus stolonifer, and stored them for 12 days.

One set of tomatoes were stored under refrigeration conditions (15 °C, 80% humidity) while the other set was illuminated with SafeLight technology under the same conditions.

The latter set of tomatoes showed visibly lesser deterioration condition on its surface after 12 days, effectively preventing mould growth.

Dr Ghate told us that the firm is working towards commercialising its technology and expanding to a wider range of applications beyond the food industry.

“Continuous disinfection is a requirement of every market segment - from healthcare and hospitality to public transport and real estate. We are in the process of piloting our products at not only food processing plants and commercial kitchens but also hospitals, real estate companies and airports.”

The firm is supported by NUS Enterprise through its Graduate Research Innovation Programme (GRIP).