Pack light: Kirin develops thin film deposition technology to protect contents in lightweight PET bottles

PET bottles are widely used for its transparency and stability, however its environmental burden has accelerated consumer demand for lighter PET bottles.

However, thinner bottles tend to cause more gas permeation, which is not ideal for products such as beer, wine and juices as they are sensitive to oxygen, carbon dioxide, and water vapour, affecting its shelf-life.

Various gas-barrier technologies have been developed to reduce gas permeation, but these often also reduced the transparency of the bottle, limiting the range of drinks that can be filled, making recycling difficult.

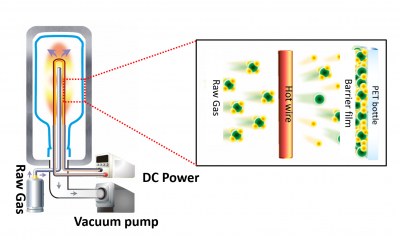

So, Kirin used the hot wire technique to develop a thin film coating based on the combination of wire and material gas species, to offer protection against gas permeation especially in lightweight PET bottles,

In a study published in 2018 in the Surface and Coatings Technology journal, Kirin and other researchers found that the combination of tantalum and vinylsilane gas forms a thin film composed of silicon, carbon and oxygen.

The technology involves filling a PET bottle with gas (vinylsilane), and a ceramic rod (hot wire) is inserted into the bottle to break down the gas, which then forms a film and deposits on the inner surface of the PET bottle. After this, the contents of the beverage are filled.

The film is expected to also help preserve the quality of the contents inside.

“By using this technology, we believe that we can contribute to reducing the amount of plastic used and food loss by extending the shelf life,” Satoru Kinoshita, manager of the Institute for Packaging Innovation at Kirin Holdings told FoodNavigator-Asia.

Kirin is in the process of commercialising this technology in its Mercian (wine) PET products.

Kinoshita added that the gas barrier thin film could be used for a wider range of beverages than conventional technology, such as those of different pH levels.

Besides beverages, it can be applied to other products, such as food containers, cosmetic packaging, supplement packaging, and other containers that require a gas barrier.

“We will work with external partners to commercialise the product in order to explore the possibility of using it not only in beverages and alcoholic beverages, but also in seasonings, food and cosmetic containers, and even in health science fields such as materials for cell culture” Kinoshita said.

In addition, Kinoshita explained that changing the combination of gas and hot wire material may create thin films with other properties, which have the potential to be used in a variety of industries beyond beverages.

This technology plays a role in Kirin Group’s environmental vision for 2025 in promoting the development of sustainable packaging and technologies to save resources.

Myanmar market

Meanwhile Kirin Holdings has announced it is cutting joint venture ties with the Myanmar Brewery and Mandalay Brewery in Myanmar, which were linked to the military, following protests against the military coup in the country.

Kirin has a 51% stake in both joint ventures, while the Myanmar Economic Holdings (MEHL) owns the rest.

However, a spokesperson from Kirin, who declined to be named, said the firm hopes to continue doing business in Myanmar.

“Kirin has been monitoring the situation in Myanmar closely with great concern and is deeply concerned by the recent actions of the military in Myanmar, which are against our standards and Human Rights Policy,

“Given the current circumstances, we have no option but to terminate our current joint venture partnership with Myanmar Economic Holdings Public Company Limited, which provides the service of welfare fund management for the military.

“At present, we are not planning on leaving Myanmar. We hope to find a way forward that will allow us to continue contribute to Myanmar’s economy and society.”