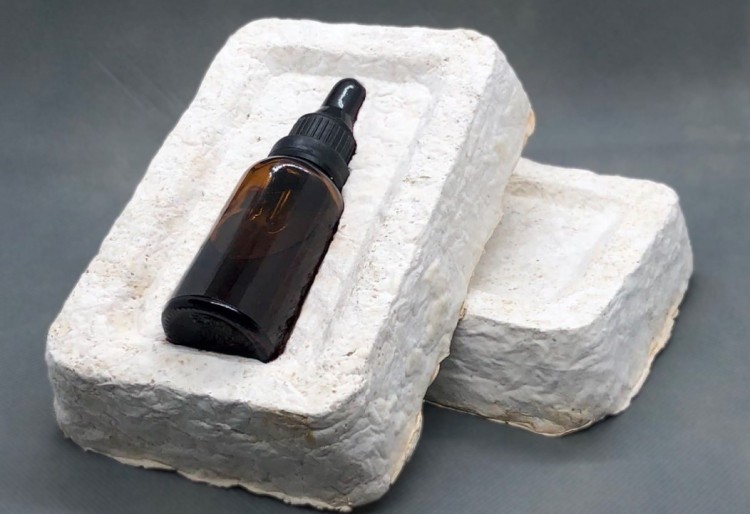

Shroom protection: Mushroom Material targets cosmetics sector with sustainable alternative to styrofoam and cardboard packaging

Made from the vegetative part of mushrooms called mycelium and fiberous agricultural waste, the material is robust to withstand impacts, yet is biodegradable within six weeks.

Suitable for products from cosmetics to cutlery, the packaging is customisable to any shape, size and surface finish, is stronger than concrete pound for pound, has a better thermal insulator than fiberglass, is odourless, mould resistant and non-toxic.

The company was founded by Shaun Seaman in 2020 after observing the huge amounts of waste material produced globally.

Seaman, who has a background in mechanical engineering, told us: “I spent most of my career designing products which required packaging, and you get a sense of guilt for almost how much material that is going straight to landfills and the oceans.

“I was conflicted from wanting to create amazing products, but at the same time, not wanting to be responsible for unsustainable practices.”

This combined with the global shift towards sustainability, was the driver in establishing Mushroom Material.

To date, over 25 countries have initiatives banning single use plastics, specifically polystyrene.

In 2021, the European Union Single-Use Plastics Directive will ban 10 single-use plastic products from all 27 countries in the EU, including polystyrene products.

In 2025, the Australian Packaging Covenant will ban all non-reusable, non-recyclable or non-compostable packaging, specifically polystyrene.

Mushroom packaging

The company mixes the roots of mushroom and fiberous agricultural waste to create its sustainable packaging.

“An important distinguishing factor for us is that we use the root structure of mushroom. Investors and consumers often get confused thinking we make mushrooms or that we’re using mushrooms to make packaging when it should be better used as food for humans,” Seaman explained.

The roots of mushroom are mixed with organic agricultural waste such as saw dust, hemp hulls, cardboard, straw or wood chips. So far, Seaman said wood-based products seem to produce the best results.

These substrates are managed under certain conditions and left to grow into mycelium, which is a network of fungal threads or hyphae. It acts as a natural adhesive and overtime can bind all the substrate together, forming a solid piece.

For instance, to make a brick shaped packaging, the raw materials are filled up in a container in the shape of a brick, and left to grow. Once it turns visually white, it is ready to be removed, after which it would be heat treated and maintain its shape until degradation begins.

R&D challenges

The company is currently focused on the R&D phase.

One of the more significant challenges was ensuring that the packaging it creates is robust enough to sit on a shelf for two years, but can also degrade in six weeks.

Particularly in humid places like Singapore, things tend to degrade faster.

The more robust the product, the longer it would take to degrade in places with dry climates.

Another challenge was supplying its substrate over the world.

“We are using a biological substance so it can’t be freely moved around the world. Particularly, New Zealand and Australia have strong border control over these things,” Seaman said.

“However, if you manufacture properly such as treated-wood, it can be sent anywhere in the world. So, one of the issues is the lack of current infrastructure because this is a new product, new material and new process. It’s understanding what is allowed to be imported and working with local governments and officials to make sure they can be accepted.”

Business model

The company is currently focused on secondary packaging, which is the exterior packaging of the primary packaging to further protect the product.

The secondary packaging is typically the first packaging that the consumer will see, making its appearance important.

Mushroom Material is initially targeting the cosmetic industry to package high value and fragile items such as perfume.

“We can create packaging that aesthetically looks good, and fits with the organic, sustainable and eco-friendly branding of most of these businesses,” Seaman said.

“Our packaging also offers good thermal insulation and good impact resistance. We are working with different industries at the moment from small appliances to small hardware like drills to cups and mugs.”

Mushroom Material intends to work with clients to create sustainable packaging designs that will easily replace and fit into existing processes.

Once the packaging is designed, the firm will manufacture the finished product.

Scale-up

The company is also registered in Singapore, although all of its R&D is conducted in New Zealand.

Depending on the clients and partnerships, the firm hopes to manufacture somewhere in South East Asia, in two years’ time.

Mushroom Material was incubated in the Eastern Pacific Accelerator powered by Techstars, this came with a US$280,000 pre-seed fund.

It is now looking to build a pilot plant in New Zealand next year, and raise another round of capital.