Kaida chooses Tomra equipment for potato processing plant

The facility in Inner Mongolia will be commissioned in Q2 2017 and have an Orbit steam peeler, a Titan whole-potato sorter and a Genius French fry sorter.

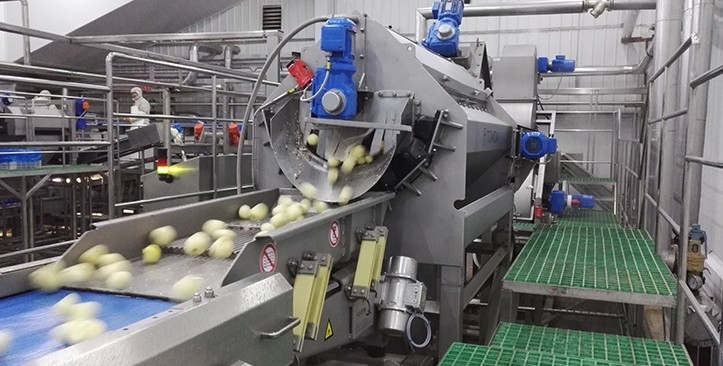

The commissioning and installation of a Tomra peeling and sorting line was launched in Kaida’s Beijing potato processing line last year operating at an average output of six tons per hour.

Kaida (Beijing Kaida Hengye Agricultural Technology Development Co.) is a vegetable and fruit chips exporter in China with products in Japan, South Korea, Australia, the US and the EU.

The company has partnerships with 7-Eleven, Pepsi Co, Kraft, Synear and Sanquan.

Liu Chang An, Kaida CEO and chairman, said: “Compared with the 10-30% peeling loss with mechanical peeling, Kaida’s new facility in Beijing has a 6% loss, which will generate an additional 1,150 – 6,900 tons of raw material savings per year.

“We undertook on-site tests at the facilities of various steam peeling solution providers, and these test results showed clearly that Tomra’s technology generates between 2-4% material savings, which means we can produce more French fries with the same amount of raw potato materials.”

The investment was in response to the 13th National Five-Year Plan - part of Chinese social and economic development initiatives - to promote potato as a staple food and modernize the processing industry in anticipation of growth in demand.

Wang Haitao, project manager for Kaida’s potato processing base in Beijing, said Tomra’s steam peeling technology has a 4-6% peeling loss which is lower than the average industry level.

“We didn’t make the decision overnight. We undertook in-depth research on various potato peeling technologies, including abrasive peeling and steam peeling, and compared the solutions offered by several suppliers,” he said.

“We also visited several French fry and potato chip processing facilities, owned by global brands, which enabled us to see with our own eyes Tomra’s steam peelers, dry peel separators, whole potato sorters and French fry sorters in action.

“Our OEM customer who also has a Tomra peeling line confirmed that steam peeling will not affect the taste or quality of the final products.”